Multi-rake Bar Screen

As the reliable, sturdy traveling screen, the Multi-rake Bar Screen is perfectly suited to serve both municipal or industrial wastewater, and process water screening.

As the reliable, sturdy traveling screen, the Multi-rake Bar Screen is perfectly suited to serve both municipal or industrial wastewater, and process water screening. The cleaning elements, attached to the chain system, can easily be adjusted to different requirements. As the cleaning elements can be variably adapted, the screenings removal capacity is then adjustable. This is especially favorable for high solids loads. The cleaning elements, consisting of the rake and comb plate, are screwed and thus independently replaceable.

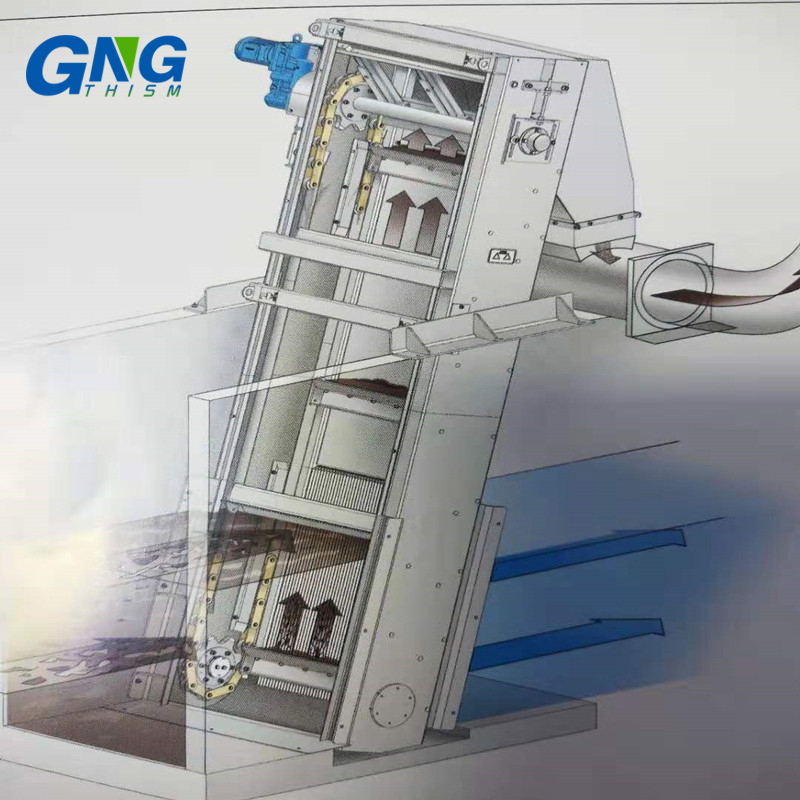

Working Principle

Due to the specific design, its height above the floor is very low and even in case of deep channels, only dependent on the installation height of the downstream screenings transport or washing system. Both ends of the cleaning elements are connected to drive chains. Each chain is driven by a sprocket on a common shaft and a flange mounted gear motor. Furthermore, the defined meshing of the cleaning rakes with the bar rack ensures high operating reliability. An electro-mechanical overload protection system(spring assembly with deflection monitoring) reliably ensures that the process is interrupted when the preset overload is reached, or in case of a blockage.

Main Features

– Very high screenings discharge capacity

– Low headloss

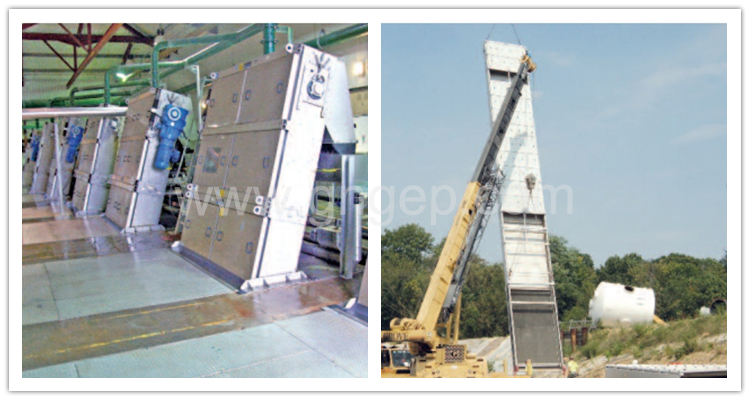

– Low installation height above ground level even in deep channels

– Very wide range of applications through innovative design options

Benefits

♦ Very low headloss but separation efficiency.

♦ Defined meshing of the cleaning rakes with the bar rack ensures high operating reliability.

♦ Screen installation possible without a bottom step.

♦ Compact design with a low installation height above ground level.

♦ Completely odor-encased screen with easy to remove covers.

♦ Easy-to-retrofit into existing channels, installation without channel recesses possible.

♦ The screen consists of a self-supporting folded stainless steel profile so that it can easily be lifted out of the channel.

♦ Not hindered by gravel or grit.

♦ Simple and easy-to-access chain tensioning unit.

♦ All parts in contact with medium( expert the chain, pinion, drive and bearing) are made of immersion pickled stainless steel, optional stainless steel chains and chain wheels.

♦ High screening discharge capacity through adjustable cleaning elements.

♦ Independently replaceable rake and comb plates.

♦ Automatic scraper mechanism, no service water required.

Installation

| Channel Widths | Discharge Height Above Channel Floor | Bar Spacing | Installation Angle |

| up to 4000mm | up to 20m | ≥1 mm | 50°~80° |